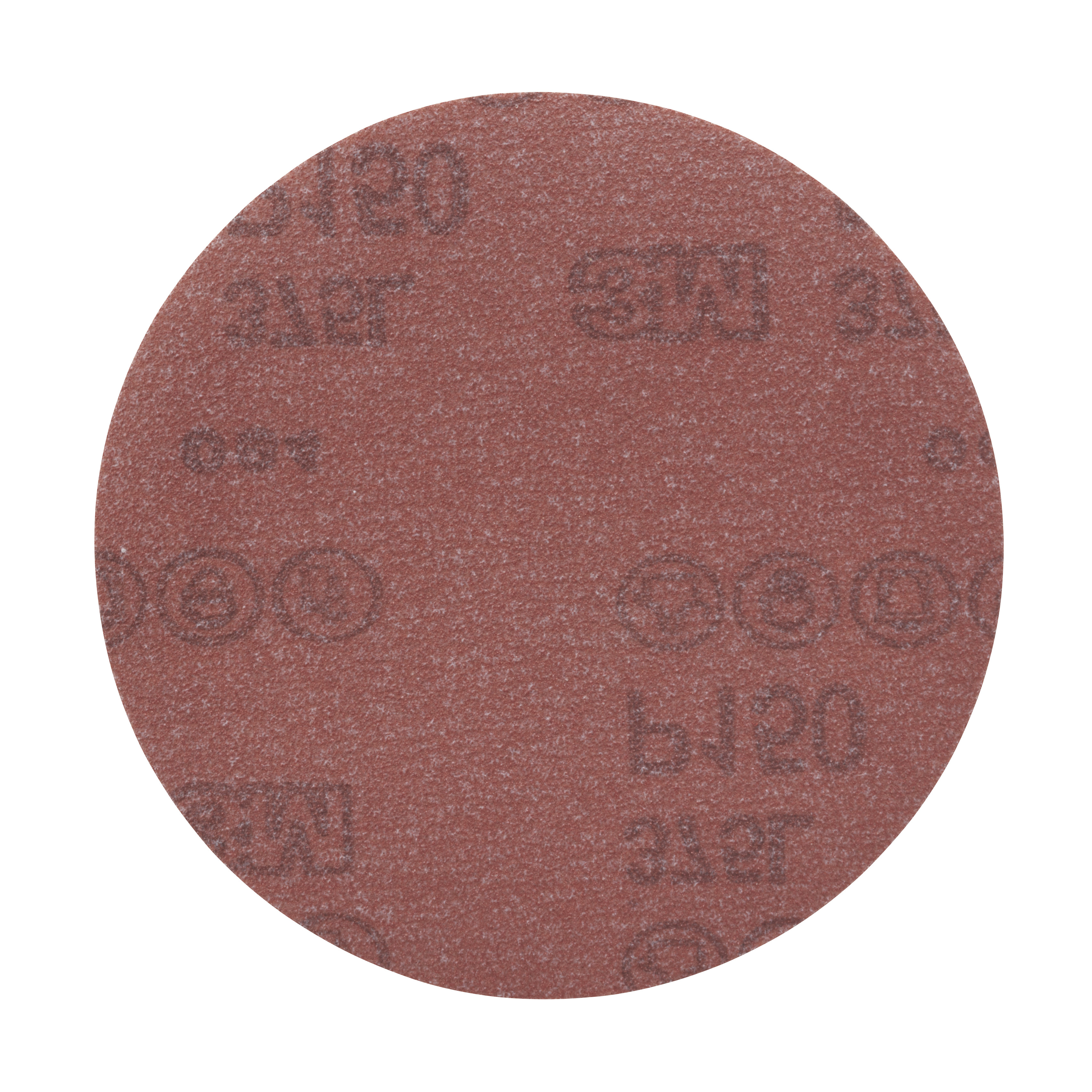

3M™ Stikit™ Film Disc 375L, 5 x NH P1000 w/skipslit liner, 50/Carton, 250 ea/Case

Product Description

This durable film construction provides the tear resistance needed for the use of coarse grades in high-production metalworking environments, particularly where edge wear is a concern. The film backing generates a uniform and consistent finish. With a 3M™ Stikit™ backing, this disc is easy to attach to a backup pad (sold separately), and easy to remove.

3M™ Stikit™ Film Disc 375L is suitable for a variety of applications. When the goal is a superior wood finish, the 375L film disc in medium grades conforms well to the contours and rounded edges of challenging work surfaces to deliver a superior finish. Woodworking applications are further enhanced by a load-resistant coating and open coat construction, which reduce clogging and extend the life of the abrasive. For pre- and post-paint finishing, versatility is key, and the 375L film disc in fine grades is designed to deliver a superb uniform finish on plastics and clear coat technologies commonly used in the transportation industry.

The 3M™ Stikit™ Film Disc 375L is designed for use with a random orbital sander and our Stikit™ backup pad (sold separately). It comes in a range of grades for various applications from rough sanding to very fine finishing.

The line of Stikit™ discs come ready to use with a pressure sensitive adhesive coating on the backside so that attaching them to the Stikit disc pad is as simple as pressing on a sticker. And because the adhesive is pressure sensitive, the disc can be peeled off of the disc pad just as easily, leaving a clean surface for the next disc. A convenient liner prevents the adhesive from becoming dirty and keeps the backing sticky until applied.

Film-backed discs have excellent tear-resistant properties and provide a very uniform finish and consistent results with each use. This makes them an excellent option when working on paint, e-coats, primers, gel coats, glass, acrylics and solid surface material, wood topcoats and anywhere else a perfect finish is needed.

An aluminum oxide abrasive mineral is featured in the manufacture of our 3M™ Stikit™ Film Disc 375L. Aluminum oxide is a popular choice among industrial professionals because of its fast cut-rate and long life. This mineral makes a tough, durable abrasive that self-fractures to expose fresh cutting edges, whereas traditional natural abrasives dull more quickly. Due to its fast cut-rate, hardness, and strength, it is widely used in grinding applications in addition to sanding and finishing applications. Aluminum oxide is suitable for a wide variety of materials in both woodworking and metalworking, including ferrous alloys.

Product Features

| Abrasive Material | Aluminum Oxide |

|---|---|

| Application | Finishing, Sanding |

| Attachment Type | PSA |

| Backing Material | Film |

| Center Hole Diameter | 0.0 NP |

| Grit | P1000 |

| Industries | AOEM, Composite, Metalworking, Paint Preparation, Transportation & Heavy Equipment, Woodworking |

| Overall Diameter | 5.0 in |

| Product Color | Reddish Brown |

| Sub Applications | AOEM Finish Prep/Repair |

Product Highlights

- Premium aluminum oxide abrasive offers a fast cut and long life, and performs well on many surfaces

- 3M™ Stikit™ backing provides easy application and removal, and a liner prevents dust and debris from contaminating the adhesive

- Durable film backing is tear-resistant and provides a uniform, consistent finish

- Open coat construction provides an aggressive cut

- Load-resistant coating helps prevent dust and debris from clogging the disc

- Excellent for contoured surfaces

Need Sales Help?

Contact Us