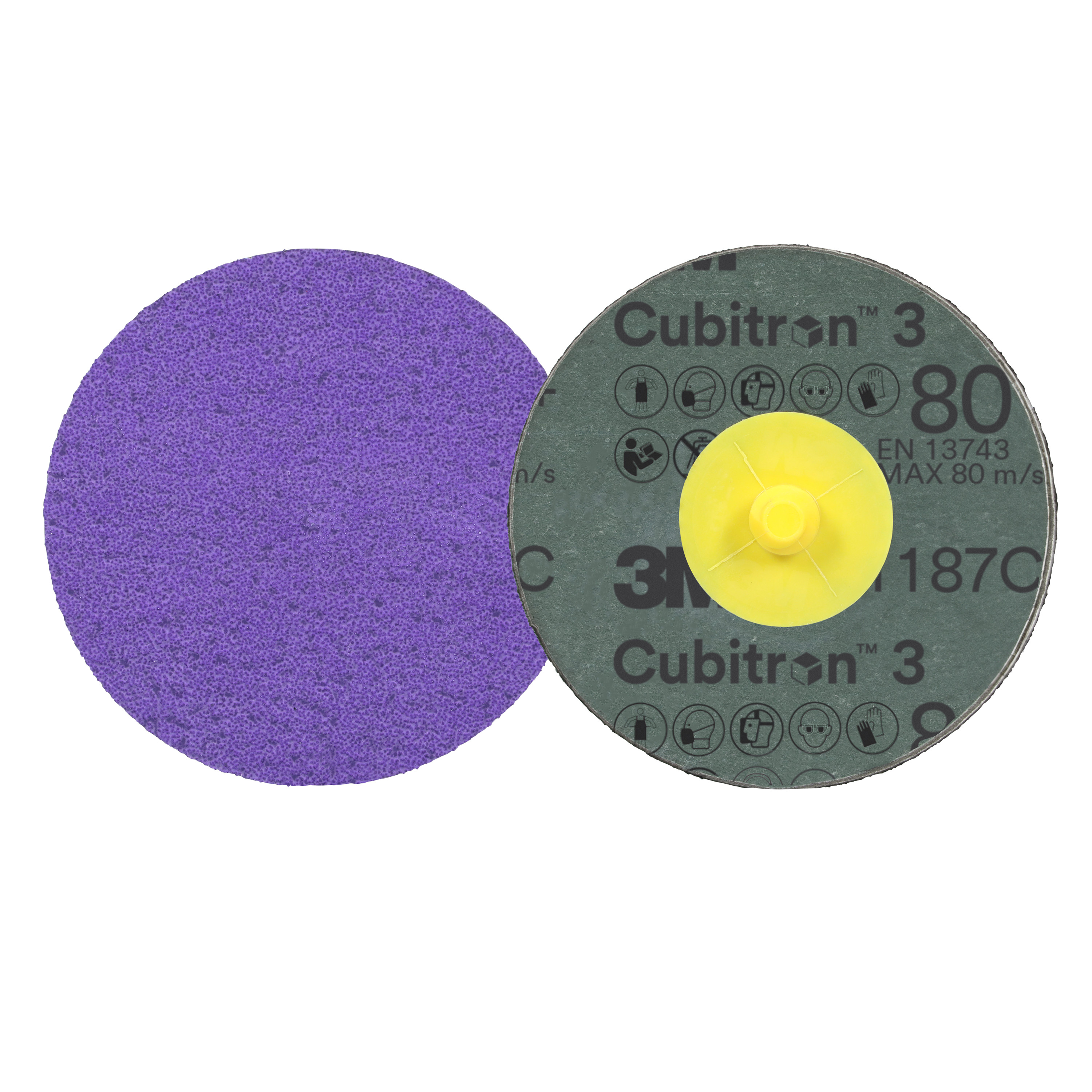

3M™ Cubitron™ 3 Roloc™ Fibre Disc 1187C, 80+, TR, Purple, 2 in, Die R200P, 50/Carton, 200 ea/Case

Product Description

The 3M™ Cubitron™ 3 Roloc™ Fibre Disc 1187C is engineered to help operators take on a variety of tasks with less fatigue. This is made possible through this disc's exceptionally high cut rate that requires less pressure than conventional abrasives, combined with the added benefit of an incorporated grinding aid to help keep the disc cooler on heat-sensitive metals, reducing metal discoloration/oxidation and the chance of heat-related stress cracks. This disc's stiff fiber backing and strong resin bond provide durability and tear resistance to help ensure operators can work on medium to high-pressure grinding projects — jobs made even easier thanks to re-engineered 3M Precision-Shaped Grain, which slices cleanly through metal, wears evenly, and continuously self-sharpens as the points break off.

Product Features

| Abrasive Material | Precision Shaped Ceramic |

|---|---|

| Application | Blending, Blending Corners, Grinding, Metal Stock Removal, Stock Removal, Surface Finishing, Weld Grinding, Weld Removal |

| Attachment Type | TR |

| Backing Material | Fibre |

| Backing Thickness | 0.0 NP |

| Backing Weight | Non Pertinent |

| Center Hole Diameter | 0.0 NP |

| For Use On | All Metal |

| Grit | 80+ |

| Hole Configuration | R200P |

| Industries | Metalworking |

| Maximum Speed | 25000.0 |

| Maximum Speed UOM | rpm |

| Overall Diameter | 2.0 in |

| Product Color | Purple |

Product Highlights

- OPTIMIZED MINERAL: The curved sides of Re-Engineered 3M Precision-Shaped Grain help to maintain sharp points that cut exceptionally fast with less pressure

- ADDITIONAL FEATURES: An incorporated grinding aid helps minimize grinding temperatures for stainless steel and other heat-sensitive alloys

- BUILT TOUGH: A stiff fiber backing and strong resin bond provide durability and tear resistance, not only for heavy grinding applications and beveling, but — thanks to the variety of mineral grades offered — also for medium-pressure surface grinding, weld removal, blending, and robotic operations

- COOL CUTTING: Features a grinding aid and requires less pressure to use, enabling predictable wear while helping to reduce metal discoloration and the risk of stress cracks on heat-sensitive alloys, such as stainless steel, and non-ferrous metals

- LONG-LASTING: Maintains sharp points that cut exceptionally fast along the entire life of the fibre disc across a range of application pressures

- STAY PRODUCTIVE: Designed for significantly longer disc time, this disc delivers more parts completed per disc while cutting down on abrasive waste, reducing changeouts or downtime

Need Sales Help?

Contact Us