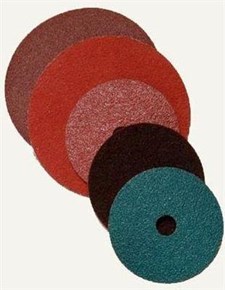

Scotch-Brite™ Roloc™ Precision Heavy Duty Surface Conditioning Disc, HD-DR, X-Extra Coarse 60+, TR, 3 in, 25/Carton, 100 ea/Case

Product Description

The cutting performance of 3M Precision-Shaped Grain is only half of the equation for what makes Scotch-Brite™ Precision Heavy Duty Surface Conditioning Discs so effective. The other element to their construction is tried-and-true Scotch-Brite™ Nonwoven Web Technology, which is made from nylon and abrasive mineral and strengthened with resin. The fibers and sharp abrasive particles are bound together to form an open, three-dimensional structure that allows fresh abrasive to be exposed as the disc wears, resulting in longer life and more consistent performance. This combination of cutting power and anti-load technology help extend the life of the abrasive product while improving finish consistency. Choose Scotch Brite™ Precision Heavy Duty Surface Conditioning Discs to complement, elevate, and enhance your finishing process.

Product Features

| Abrasive Material | Precision Shaped Ceramic |

|---|---|

| Application | Blending, Blending Corners, Deburring, Deburring Edges, Edge Chamfering, Finishing, Light Deburring, Light Grinding, Prepping Metal Prior to Paint, Refining, Refining Scratches, Surface Preparation, Surface Preparation for Painting |

| Attachment Type | TR |

| Backing Thickness | 0.0 NP |

| Backing Weight | Non Pertinent |

| Center Hole Diameter | 0.0 NP |

| For Use On | All Metal |

| Grit | 60+ |

| Hole Configuration | Non Pertinent |

| Industries | Aerospace, Food & Beverage, General Industrial, Heavy Industrial, MRO, Machinery Manufacturing, Metal Fabrication, Metalworking, Paint Preparation, Transportation & Heavy Equipment |

| Maximum Speed | 20000.0 |

| Maximum Speed UOM | rpm |

| Overall Diameter | 3.0 in |

| Sub Applications | Blending |

Product Highlights

- TOUGH ENOUGH FOR HEAVY-DUTY USE: Designed for high-pressure applications, such as grinding, deburring, edge breaking, blending, and refining

- HIGH PERFORMANCE: Grade XXCRS lasts 2X longer on mild steel compared to competitive premium nonwoven abrasives (based on 3M internal testing) — while offering edge durability and shape retention during edge wear

- PROCESS OPTIMIZATION: Grade XXCRS (60+) on mild steel processes 3X more parts than competitive premium nonwoven abrasives (based on 3M internal testing)

- THE SCOTCH-BRITE™ DIFFERENCE: Fibers and sharp abrasive particles are bound together to form an open, three-dimensional structure that allows fresh abrasive to be exposed as the disc wears, resulting in longer life and helping to deliver consistent performance

- TWO INNOVATIVE TECHNOLOGIES IN ONE DISC: Scotch-Brite™ nonwoven fibers combined with 3M Precision-Shaped Grain deliver improved performance over traditional surface conditioning discs

- WORKS ON A RANGE OF METALS: Made for use on aluminum, mild steel, nickel alloy, stainless steel, and copper

Need Sales Help?

Contact Us