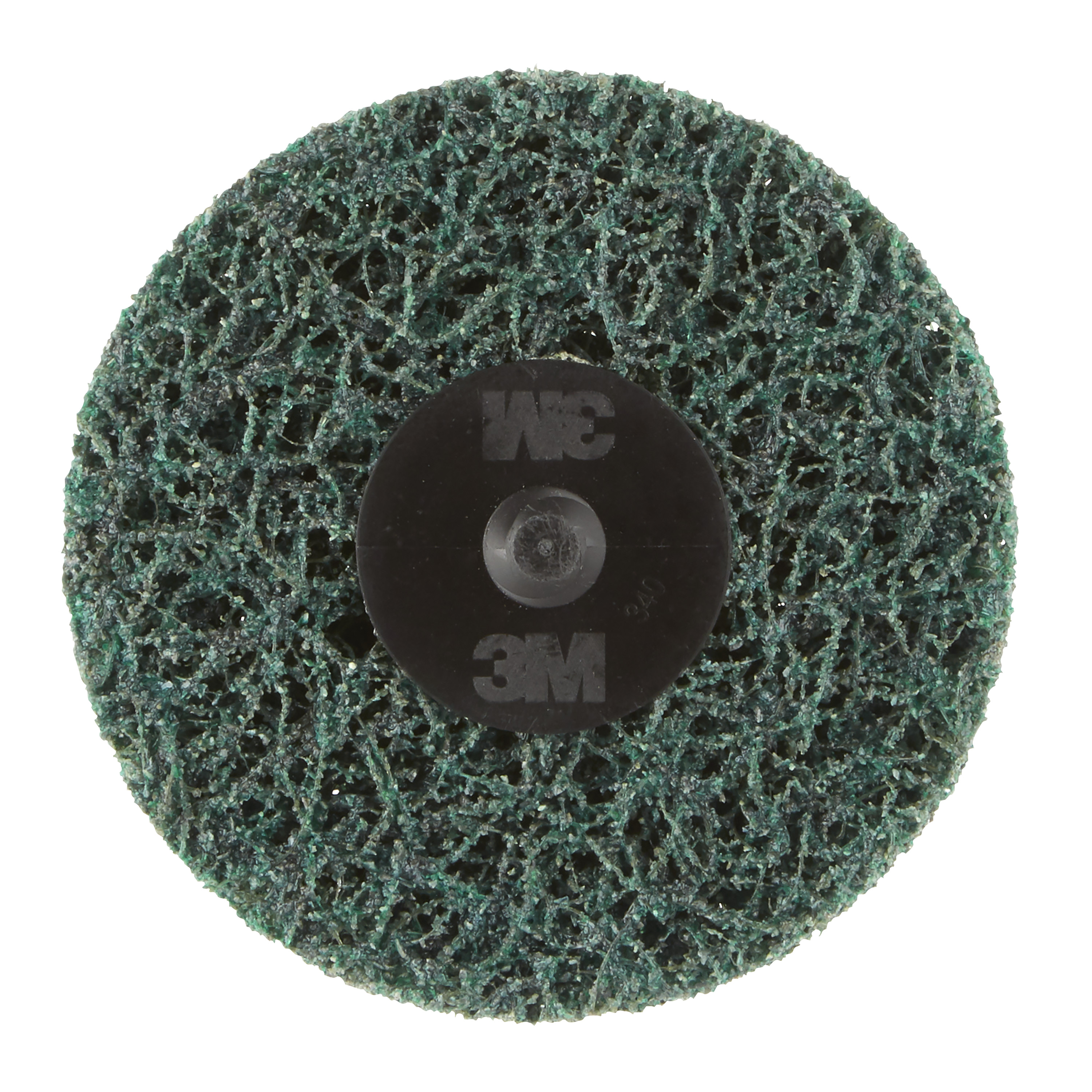

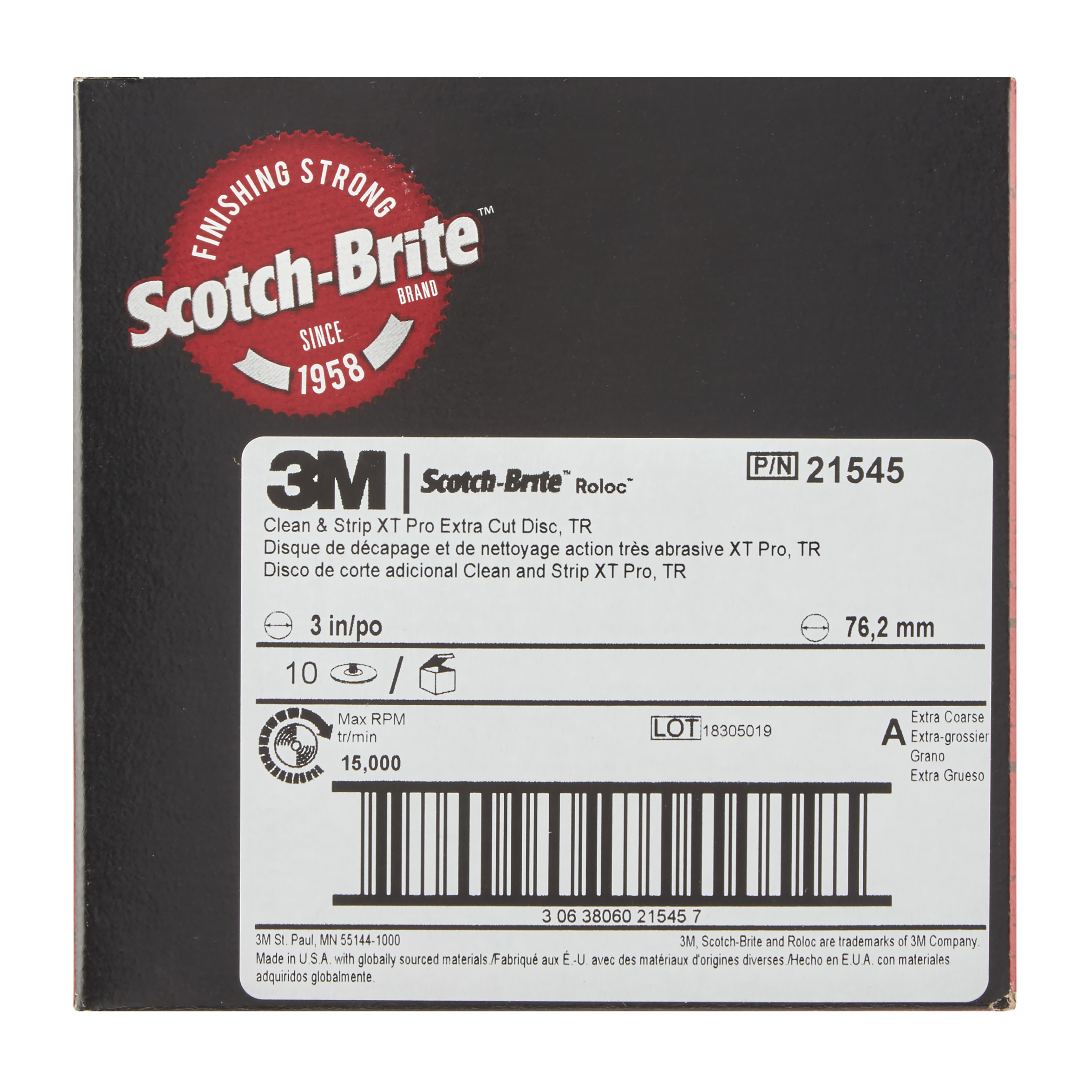

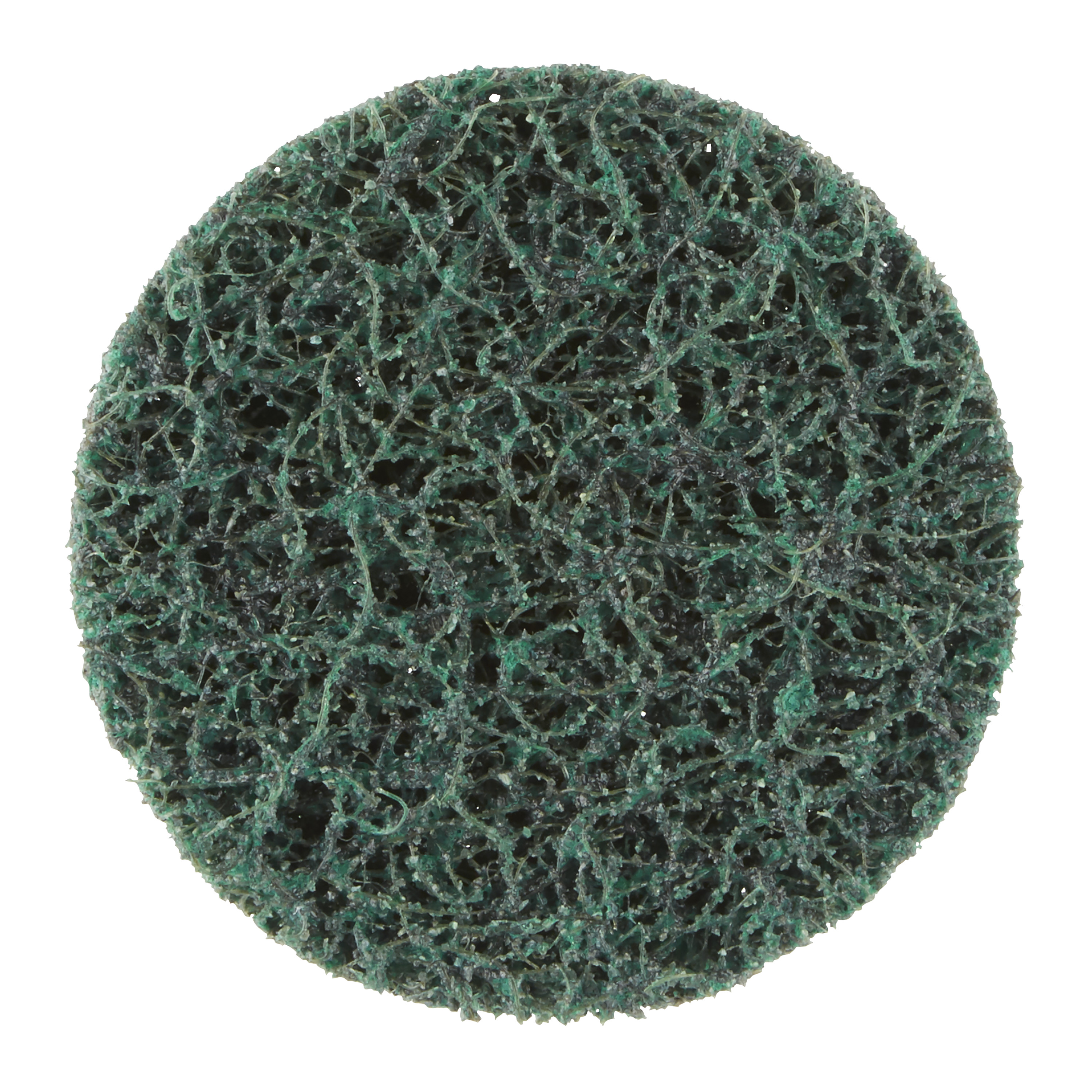

Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc, XC-DR, A/O Extra Coarse, TR, 3 in, 25 ea/Case

Product Description

Take Advantage of High Conformability

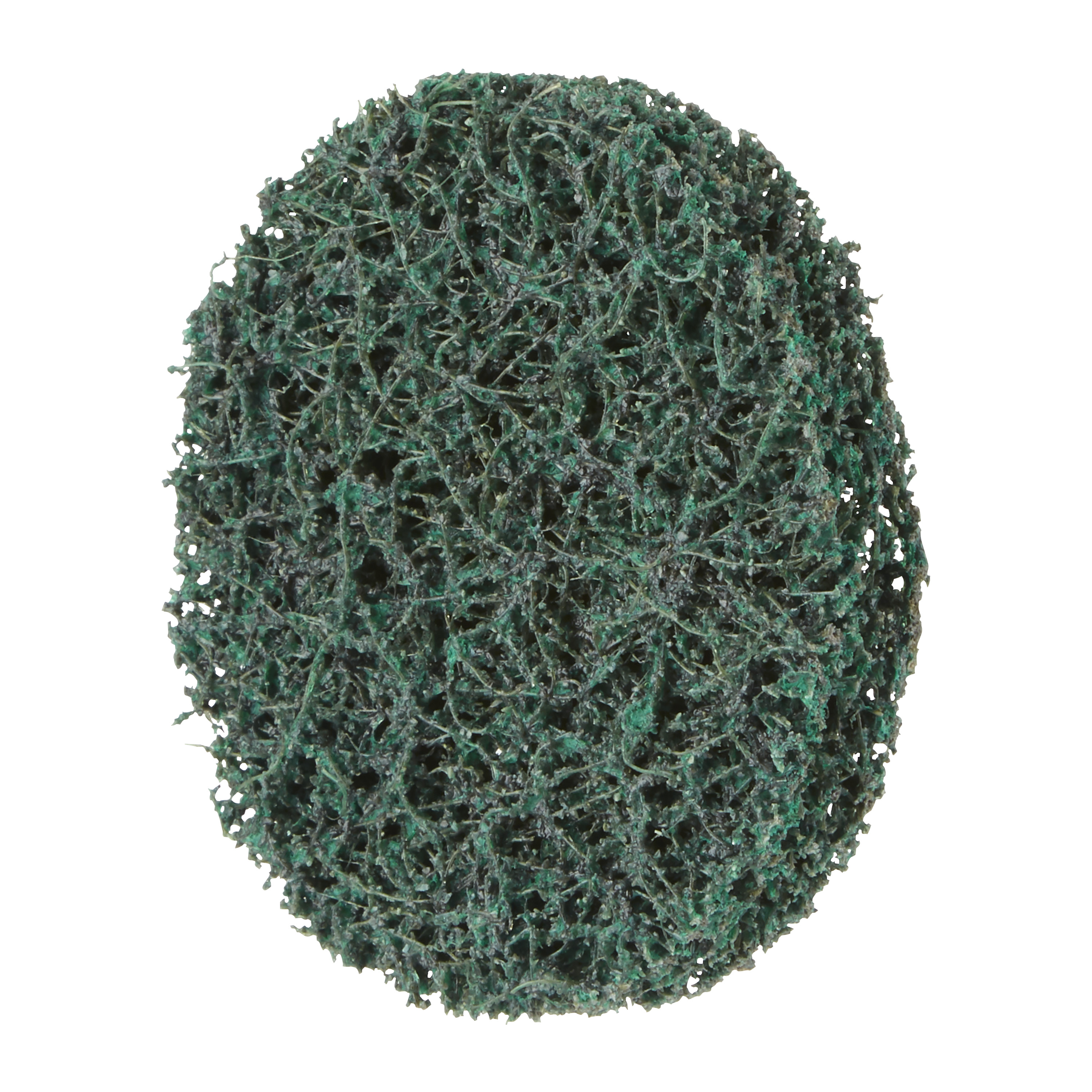

With its reengineered fiber type, the Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc allows operators to take advantage of all the benefits that come with increased conformability without compromising strength. With increased conformability, this disc achieves a larger contact area with the workpiece for faster removal rates. It also conforms to weld bead ripples to polish welds without removing them, and works in hard-to-reach areas without damaging the substrate.

In addition to its high conformability, the Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc offers low vibration, decreased chunking, a high speed rating and long life. That all adds up to a disc you can spin onto your angle grinder with confidence.

Save Time with Aluminum Oxide

3M designed their Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc with aluminum oxide abrasive mineral because of its ability to remove heavy coatings and simultaneously scratch and clean to the bare metal underneath without leaving divots. This means that operators can remove a coating from a workpiece and get it ready for welding or adhesive application with the same disc – saving the time of switching abrasives.

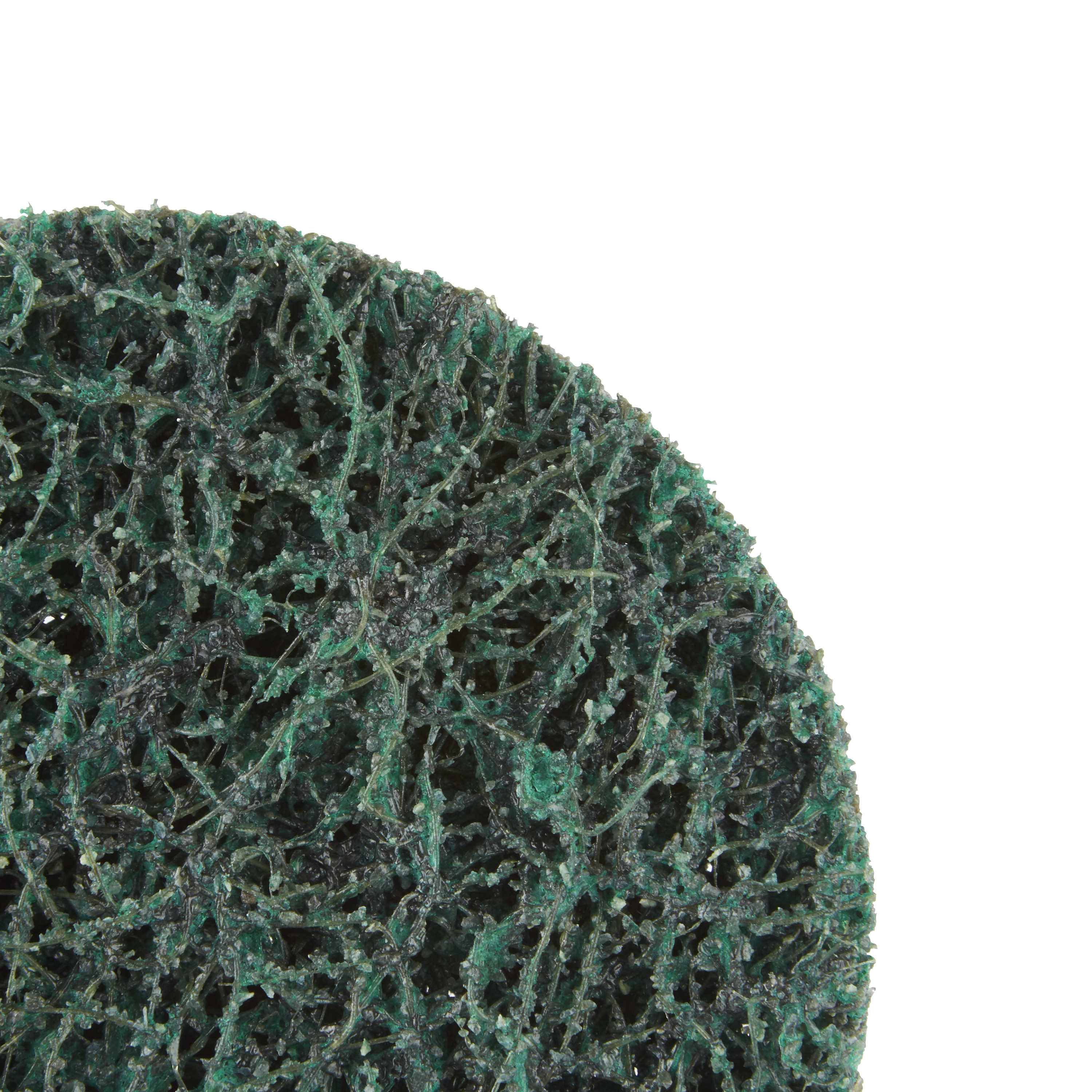

Spongy Web, Sharp Mineral

To engineer the Scotch-Brite™ Roloc™ Clean and Strip XT Pro Extra Cut Disc, aluminum oxide mineral is combined with non-woven nylon fibers using resin. Aluminum oxide is a very hard mineral that delivers a high cut rate, commonly used in high-pressure applications like cutting and weld removal. The resin bond strengthens the fiber web and allows it to gradually break down to reveal new fibers and sharp mineral – delivering a consistent cut over the life of the abrasive. The combination of fiber strands, resin and abrasive mineral forms a thick, open web. Gaps in the web allow swarf to escape, minimizing loading of the abrasive.

Roloc™ Makes Tool Attachment Easy

This disc comes with the added benefit of a Roloc™ attachment. Operators can quickly and swiftly attach the disc to a Roloc™ backup pad (sold separately) that connects to the power tool. Altogether, Roloc™ attachment systems help enhance productivity by minimizing the time it takes to set up disc and tool connections.

Applications

Removing heavy rust

Removing rust pits

Removing thick paint

Removing corrosion

Removing weld discoloration

Weld cleanup

Product Features

| Abrasive Material | Aluminum Oxide |

|---|---|

| Application | Coating Removal, Corrosion Removal, Descaling, Mill Scale Removal, Oxide Removal, Paint Preparation, Paint Removal, Paint Stripping, Rust Removal, Sealant Removal, Strip Paint to Metal, Stripping, Surface Preparation, Surface Preparation for Painting, Weld Preparation, Weld discolouration removal (stainless steel) |

| Attachment Type | TR |

| Backing Thickness | 0.0 NP |

| Backing Weight | Non Pertinent |

| Center Hole Diameter | 0.0 NP |

| For Use On | Aluminum |

| Grit | Non Pertinent |

| Industries | Collision Repair, Food & Beverage, General Industrial, Heavy Industrial, MRO, Machinery Manufacturing, Manufacturing, Metal Fabrication, Metalworking, Mining, Oil & Gas, Rail, Transportation & Heavy Equipment |

| Maximum Speed | 15000.0 |

| Maximum Speed UOM | rpm |

| Overall Diameter | 3.0 in |

| Product Color | Green |

| Sub Applications | Coating Removal |

Product Highlights

- QUICK REMOVAL: Efficiently removes heavy rust, thick paint, corrosion and cleans welds while providing fast and effective removal

- AGGRESSIVE ALUMINUM OXIDE MINERAL: Removes the top layer and cleans to the bare metal underneath with its aggressive cutting action

- HIGH CONFORMABILITY: Offers a larger contact patch, resulting in faster removal rates

- HIGH-STRENGTH FIBER: Resists chunking and performs exceptionally well on edges

- RESISTS LOADING: Maintains consistent cutting action by preventing clogging and loading

- HIGH SPEED RATING AND LOW VIBRATION: Provides efficient performance with minimal vibration for improved user experience

Need Sales Help?

Contact Us