Scotch-Brite™ Roloc™ SL Surface Conditioning Disc, SL-DM, A/O Medium, TSM, Config

Product Description

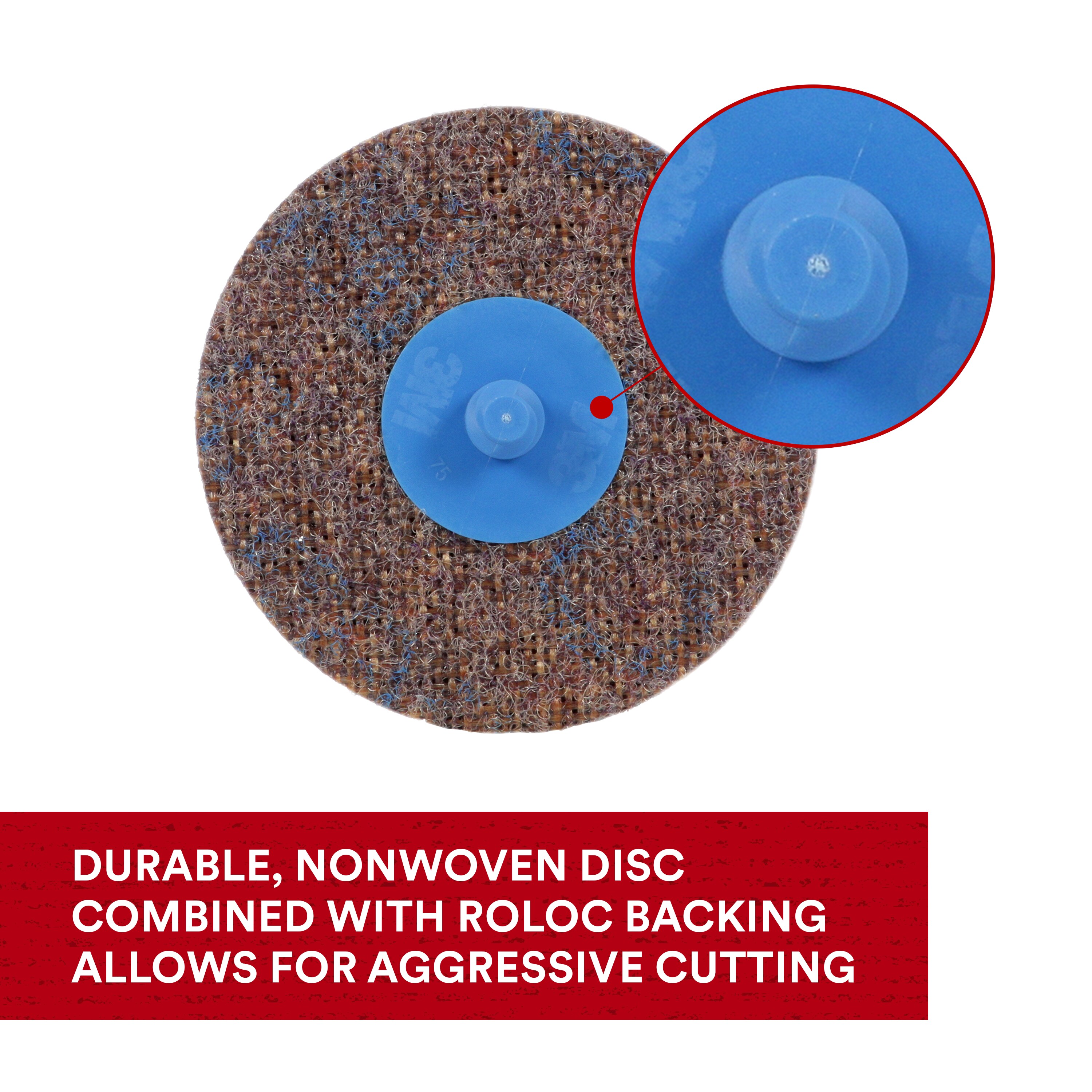

With this versatile capability, Scotch-Brite™ Roloc™ SL Surface Conditioning Discs can reduce or eliminate subsequent conditioning steps for weld clean up, grindline refinement, metal blending, and even light deburring. Available in four grades: Medium, Coarse, Heavy Duty and Super Duty, the open-web, non woven SL disc runs cool, resists loading, and maintains cut-rate consistency throughout the life of the disc. These same attributes allow you to use less pressure, reducing fatigue and maximizing disc life.

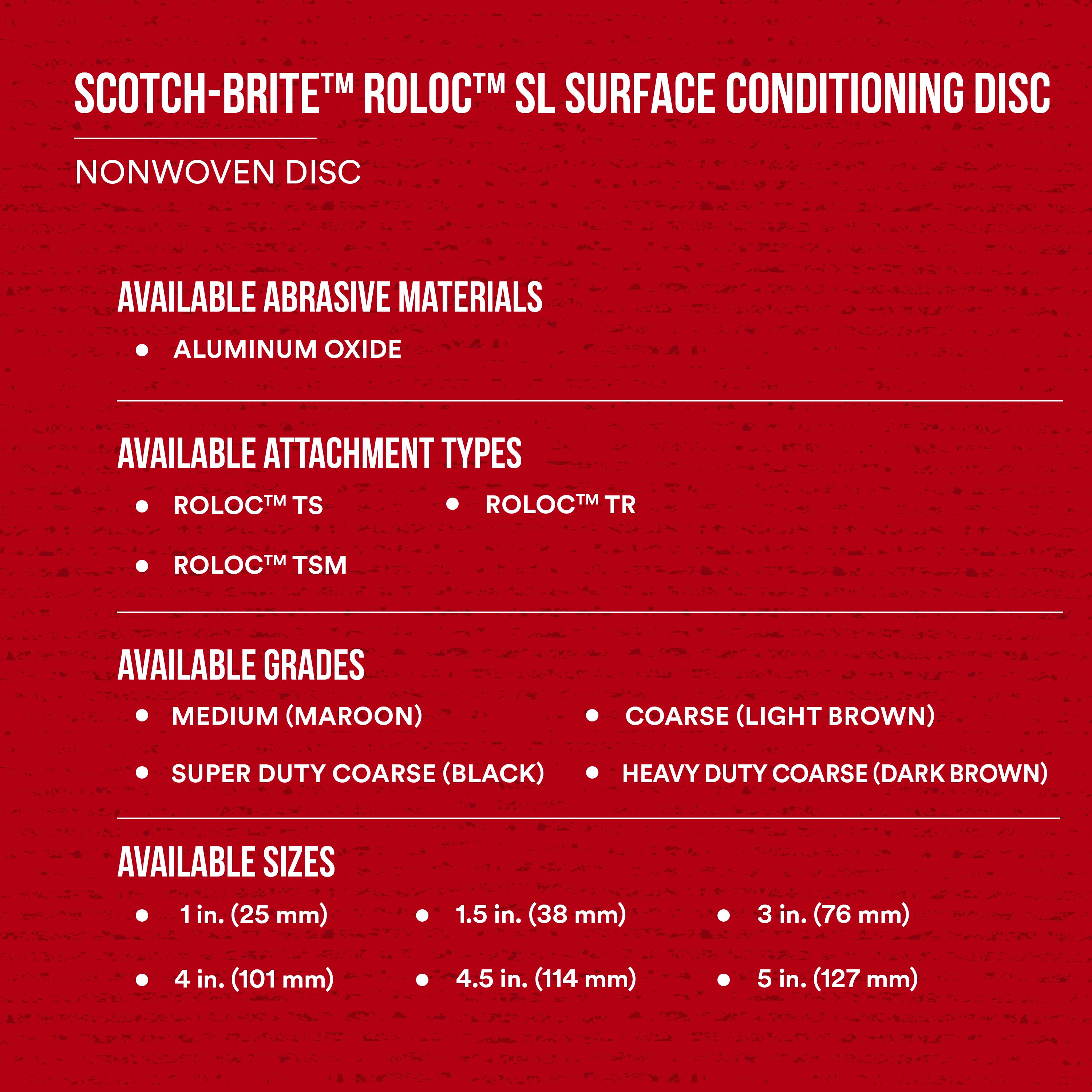

Aluminum oxide abrasive mineral is used in the Scotch-Brite™ Roloc™ SL Surface Conditioning Disc. Aluminum oxide is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide is widely used in grinding applications in addition to sanding and finishing use. Aluminum oxide is suitable on a wide variety of substrates in both woodworking and metalworking, including ferrous alloys.

3M™ Roloc™ TR quick change discs are smaller discs that quickly attach onto a Roloc™ disc pad (sold separately) so that you can conveniently and quickly change discs as needed. Roloc TR and TSM systems provide a secure attachment even for heavy-duty applications, and the variety of other 3M Roloc discs allow swapping from one application to the next in seconds. Each disc is also color-coded to identify its grade, making it easy to grab the grade required for different applications.

Scotch-Brite™ surface conditioning products were developed with abrasives incorporated into non-woven nylon or synthetic fibers. Combining abrasives with the fibers creates an abrasive system that delivers consistent results for the life of the product. The open-web material runs cool, reducing the risk of part discoloration and warping. The fibers are load resistant and keep the abrasive minerals cutting at high performance by limiting clogging of the fibers, which also extends the life of the disc.

Product Features

| Abrasive Material | Aluminum Oxide |

|---|---|

| Application | Blending, Deburring, Finishing, Radiusing, Refining |

| Attachment Type | TSM |

| Backing Material | Non Pertinent |

| Backing Thickness | 0.0 NP |

| Backing Weight | Non Pertinent |

| Center Hole Diameter | 0.0 NP |

| For Use On | Aluminum |

| Grit | Non Pertinent |

| Hole Configuration | Non Pertinent |

| Industries | Food & Beverage, General Industrial, Heavy Industrial, Machinery Manufacturing, Manufacturing, Metal Fabrication, Metalworking, Paint Preparation, Transportation & Heavy Equipment |

| Maximum Speed | 0.0 |

| Maximum Speed UOM | NP |

| Overall Diameter | 0.0 NP |

| Product Color | Maroon |

| Sub Applications | Blending |

Product Highlights

- BUILT FOR VERSATILITY: Makes quick work of blending, deburring, finishing, grinding, radiusing, refining and surface preparation

- LONG-LASTING PERFORMANCE: Specially engineered for durability and long abrasive life

- WORKS ON A RANGE OF METALS: Great for use on aluminum, mild steel, nickel alloy, stainless steel and titanium

- QUICK AND EASY ATTACHMENT: Convenient 3M™ Roloc™ attachment system allows for fast disc changes

- TOUGH ENOUGH FOR HEAVY-DUTY USE: Combination of aluminum oxide grain and moderate conformability makes for a tough, durable surface conditioning disc

- AVAILABLE IN A RANGE OF GRADES: Choose from Medium (MED), Coarse (CRS), Heavy-duty (CRS HD) and Super Duty (CRS SD) to fit your application needs

Need Sales Help?

Contact Us